DEAD ENDS. TECHNICAL SPECIFICATIONS

The dead-ends have the main function to fix a pole the cables, conductors, strands, structures, insulators, etc. The area of the loop always must be protect with a suitable thimble, pulley, insulator etc.

Identification

SAPREM has created a denomination that together with the number of rods, diameter, length and colour code, allows us to recognize the accessory.

The denomination of SAPREM for the dead ends is the following:

Retención de Anclaje (dead end in English) with two letters meaning the raw material which they are made from, AL (Aleación de aluminio=Aluminium alloy), AC (Acero galvanizado=Galvanized steel), AW (Aluminium Clad Steel-ACS), CW (Copper Clad Steel-CCS), AA (Acero aluminizado=Aluminized steel), following with some numbers, they show the suitable diameter for which it has been made. As you can see in the attached tables each dead end has a suitable diameter range. The dead ends for aluminium, aluminium-steel, aluminium-ACS conductors are not identified like this way. Its denomination is RALAA.

Example: RAAC 073-077/Izda (left) is a steel dead end for a cable with a diameter from 7,30 to 7,70 mm for a cable left hand lay.

Besides the colour code of the fitting is the crossover marks, indicate starting point for application. This denomination is completed with the letter D if it is right hand lay, or with the letter I if it is left hand lay.

VERY IMPORTANT: The lay direction of the fitting must be identical, to the outer layer of the specified conductor.

Finish and Appearance

The rods of the helical dead-ends are refaced in the ends to avoid damages in the application and to the specified cable.

The inside of the dead end is gritted with a non-slip material under Saprem specification ESP 06.01.08.

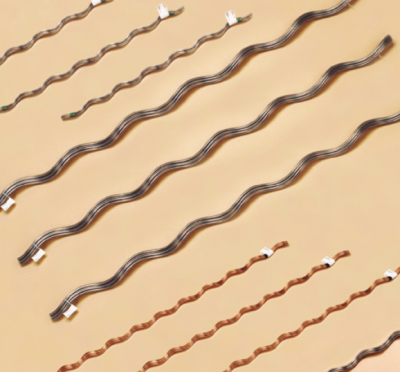

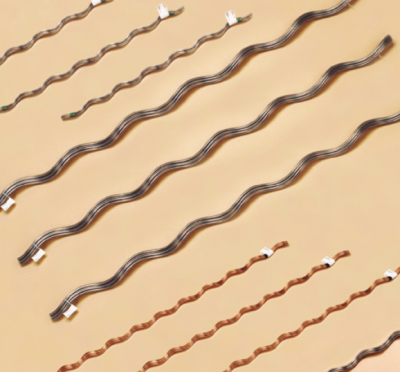

All solutions in dead ends

SAPREM offers a wide range of solutions:

SAPREM offers a wide range of solutions:

- Galvanized steel dead end -For steel cables or strands-

- Aluminized steel distribution-grip dead end -For Aluminium, Aluminium-Steel, Aluminum-ACS Conductors-

- Copper-clad steel anchor (CCS) dead end -for copper conductors-

- Aluminium clad steel (ACS) dead end -for ACS cables or strands-

If you want to know all the technical specifications, download the PDF document.

Double loop a pole dead end TECHNICAL SPECIFICATIONS

The double loop dead ends have the main function to fix a pole with the cables or strands by double round (double loop).

Identification

SAPREM has created a denomination that together with the number of rods, diameter, length and colour code will allow us to recognize the accessory.

The Saprem denomination for the double loop a pole dead end is the following:

“Retención de Amarre a Poste”= Double loop a pole dead end with two letters meaning the raw material they are made from. AC (Acero galvanizado=galvanized steel), AW (ACS), following with the numbers showing the suitable diameter for which it has been made. As you can see in the attached tables each (SEE PDF document) double loop a pole dead end has a diameter range for the application. Is necessary to know the diameter of the pole in which is going to be fixed.

Example: RAPAC 073-077/Izda is a double loop a pole galvanized steel dead end for a cable with a diameter from 7,30 to 7,70 mm, and with left hand lay. Besides the colour code of the fitting , it is marked the crossover marks, indicate starting point for application in the cable.

This denomination is completed with the letter D if it is right hand lay or with the letter I if it is left hand lay.

VERY IMPORTANT: The lay direction of the fitting must be identical, to the outer layer of the specified conductor.

Finish and Appearance

The rods of these dead end are refaced in the ends to avoid damages in the application and to the specified cable.

The double loop a pole dead end is gritted inside with a non-slip material in the contact area, under Saprem specification ESP 06.01.08.

If you want to know all the technical specifications, download the PDF document.

ALUMINIUM ALLOY DEAD END COATED WITH NEOPRENE TECHNICAL SPECIFICATIONS

The aluminium alloy dead ends coated have the main function to fix the messeger cable to a pole, to the structure, front of a house, etc. The area of the loop always must be protected with a suitable thimble.

Identification

SAPREM has created adenomination that together with the number of rods , diameter, length and colour code will allow us to recognize the accessory.

The Saprem denomination for the dead end coated used for neutral coated messenger is the following:

Retención de Anclaje Neutro fiador de Aluminio=Dead end coated for aluminium neutral coated messenger cable with some numbers indicating the suitable diameter, for which it has been made.

Example: RANAL 12,65 is a dead end for a neutral coated cable with a exterior diameter of 12,65 mm. This cable is the D-54,6.

Finish and Appearance

The rods of the fittings are refaced in the ends to avoid damages in the application and to the specified cable. All the dead ends are gritted inside a non-slip material under Saprem specification ESP 06.01.08. In the same way the dead ends are coated with neoprene under Saprem specification ESP 06.01.09.

If you want to know all the technical specifications, download the PDF document.

SIDE TIES. TECHNICAL SPECIFICATIONS

The side ties have the main function to fix the conductor, to the lateral groove of the insulator.

Identification

SAPREM has created adenomination that together with number of rods, diameter, length and colour code will allow us to recognize the accessory.

The Saprem denomination for the side ties is the following:

Retención Lateral Omega = Side tie, with two letters meaning the raw material which they are made from, AL (Aleac. aluminio=Aluminium alloy), AC (Acero galvanizado=galvanized steel), AW (ACS), CW (CCS), AA (Acero aluminizado=aluminized steel), following with some numbers, they show the suitable diameter range for which it has been made. As you can see in the attached tables each (SEE PDF document) each side tie has a suitable diameter range of application.

Example: RLOAA 093-099 is a aluminized steel for a conductor with a diameter from 9,31 to 9,90 mm. Must be added the type of insulator.

Besides the colour code of the conductor for which they are made, it is marked the colour of identification of the insulator. This denomination is completed with the letter D if it is right hand lay, or with the letter I if it is left hand lay.

VERY IMPORTANT: The lay direction of the fitting must be identical, to the outer layer of the specified cable.

Finish and Appearance

The rods of the fitting are refaced in the ends to avoid damages in the application and to specified cable. The RLO (SAPREM denomination) side ties are made into a ring, in such way that they fit in the groove of the insulator. All the side ties are supplied with a neoprene pad, it is put in the contact area between the conductor and the insulator to protect the conductor.

If you want to know all the technical specifications, download the PDF document.

All solutions in Side ties

SAPREM offers a wide range of solutions:

SAPREM offers a wide range of solutions:

- Galvanized side ties -for Aluminium, Aluminium-Steel, Aluminium-ACS –

- Aluminized steel side ties -for Aluminium, Aluminium-Steel, Aluminium-ACS cables-

- Copper clad steel (CCS) side ties -for copper conductors-

If you want to know all the technical specifications, download the PDF document.

ALUMINIZED STEEL DISTRIBUTION TIES. TECHNICAL SPECIFICATIONS

The aluminized steel distribution ties have the main function to fix the cables to the head of the insulator.

Identification

SAPREM has created adenomination that together with the number of rods, diameter, length and colour code will allow to us recognize the accessory.

The denomination of SAPREM for the aluminized steel distribution tie is the following:

Retención en Cabeza Zeta de Distribución=Aluminized steel distribution tie, with the numbers, that they show the suitable diameter range for which it has been made. As you can see in the attached tables (SEE PDF document), each fitting has an application diameter range.

Besides the colour code of the cable for which they have been made, it is marked the colour identification of the specified insulator. This denomination is completed with the letter D if it is right hand lay, or with the letter I if it is left hand lay.

VERY IMPORTANT: The lay direction of the fitting must identical, to the outer layer of the specified conductor.

VERY IMPORTANT: The lay direction of the fitting must identical, to the outer layer of the specified conductor.

Finish and Appearance

The rods of the fitting are refaced in the ends to avoid damages in the application and to the specified conductor. The RCZD (distribution ties) are made a ring in such way they fit to the insulator and to the conductor. The distribution ties are supplied with a neoprene pad, it is put in the contact area between the conductor and the insulator to protect both of them.

SAPREM offers you:

- Aluminized steel distribution ties For Aluminium, Aluminum-Steel, Aluminium-ACS

If you want to know all the technical specifications, download the PDF document.

SPLICE OF COMPLETE TRACTION TECHNICAL SPECIFICATIONS

The splice of complete traction has the main function to join two equals cables or strands, the guarantee of the mechanical characteristics to a traction load is total.

Identification

SAPREM has created a denomination that together with the number of rods, diameter, length and colour code will allow us to recognize the fitting.

The denomination of SAPREM for the splices of complete traction is the following:

Empalme de Tracción Mecanica = splice of complete traction with two letters meaning the raw material which they are made from, AC (Acero galvanizado=galvanized steel), AW (ACS), following with the numbers they show the suitable diameter for which it has been made. As you can see in the attached tables (SEE PDF document) each splice has an application diameter range.

Example: ETMAC 073-077/Izda(left hand lay) is a galvanized steel splice of complete traction for a cable with a diameter between 7,30 to 7,70 mm and left hand lay.

Besides the colour code of the fitting shows the center of the fitting, and indicate the starting point for application, to join the cables. This denomination is completed with the letter D if ti is right hand lay and with the letter I if it is left hand lay.

VERY IMPORTANT: The lay direction of the fitting must be identical to the outer layer of the specified cable.

Finish and Appearance

The rods of these fittings are refaced in the ends to avoid damages in the application and to the specified cable.

All the splices are gritted inside with a non-slip material under SAPREM specification ESP 06.01.08.

- SAPREM offers you:

- Galvanized steel splice of complete traction -For steel cables or strands-

- Splices of complete traction aluminium clad steel (ACS) -For ACS cables or strands-

“The “Photovoltaic Self-Consumption Plates” project has received a grant from the Rural Development Program (RDP) 2014-2020, which is co-financed by FEADER Funds and the Government of Navarre.”

“The “Photovoltaic Self-Consumption Plates” project has received a grant from the Rural Development Program (RDP) 2014-2020, which is co-financed by FEADER Funds and the Government of Navarre.”